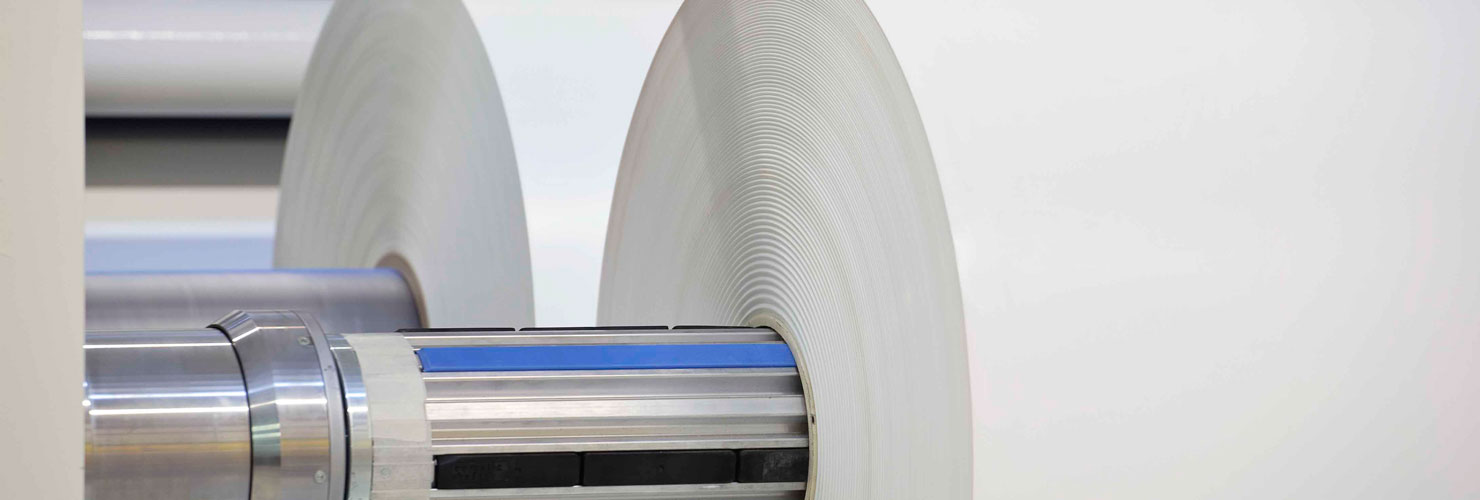

Coveme has two production sites, one in Gorizia, Italy, and the other in Zhangjiagang , China, where a total of 13 production lines are installed. The production processes are designed to improve and modify the intrinsic characteristics of the polyester film through various technologies:

- lamination

- coating

- surface treatment

- heat stabilization

- slitting

The production lines are equipped with the latest technologies, and are managed by highly qualified personnel in both plants. Both production sites have their own research and development laboratory equipped with the most advanced analytical instruments and staffed with highly skilled personnel. A third research center dedicated to new coating technologies was implemented in Germany in 2018.

During all phases of manufacturing the quality of the materials is ensured through continuous-cycle tests and data storage for each single batch, and samples of each single production batch are kept and tracked for 5 years. Furthermore, automated processes and a lean management optimize production and quality results.